Mô tả sản phẩm

Magnetic sensors

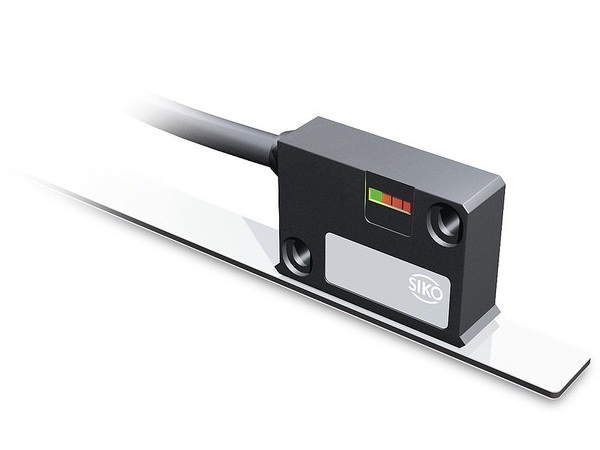

Incremental and absolute MagLine magnetic sensors

Information gathered on magnetic tapes or magnetic rings is translated by sensors and transferred to translation modules. Values measured by active sensors are converted into digital counting pulses, analog sine-cosine signals or serial absolute values. For passive sensors, combination with displays or translation modules is required.

Magnetic sensors as an inexpensive alternative to optical sensors

Magnetic sensors are hallmarked by robustness and cost efficiency. With their non-contacting design they are non-wearing and insensitive to soiling in comparison to optical sensors, for example. Magnetic sensors therefore only require little or no servicing. In addition they are more flexible during installation: The distances between the magnetic sensor and strip can be considerably larger than with an optical measuring system. The following versions are available:

+ Various sizes through to a board solution

+ Individual connector options

+ Installation in customized housing

Incremental and absolute measuring technology

When selecting a suitable sensor the first question always concerns the measuring method - incremental or absolute? Incremental measurement is popular and as a general rule also less expensive: A magnetic strip is encoded with regularly arranged north and south poles; the pole length also determines the maximum resolution and system accuracy. A sensor head which accommodates the sensor elements moves over the encoder at a defined distance and reads the magnetic fields that are processed as square wave signals (counting pulses). The distance traveled is indicated by the number of pulses.

The magnetic absolute measurement is carried out by a dual-track strip, i.e. on one side there is an incremental track, while the other track features absolute encoding. This encoding therefore only occurs once over a specific length. The advantage is that the sensor always knows its exact current position – also in a non-energized state. In contrast, in the event of a power failure the incremental method requires a reference operation to take the sensor back to a certain reference point that is then signaled back to the control unit. To avoid this process step, SIKO supplies quasi-absolute sensor solutions. The necessary measuring data are stored by means of a battery. Referencing is therefore also no longer necessary with these systems, for example after power failures. In many medical and analysis fields this preventative measure is an essential safety feature. This problem can, however, be fully avoided with the real absolute sensor technology.

Active magnetic sensor or passive magnetic sensor?

Apart from differentiating between incremental and absolute magnetic field sensors, another factor to be considered is whether the sensor is active or passive. Passive MagLine sensors supply a signal that cannot be processed externally, and for this reason must be connected to a downstream electronic system such as a MagLine measurement display or a MagLine electronic evaluation system. An active SIKO magnetic sensor already converts the received signal and has a standardized interface through which it can forward the information to a higher-level control, i.e. a downstream electronic unit. The MS sensors of the MagLine series have passive properties, while the MSK sensors run actively towards the exterior.

Magnetic length measurement and magnetic angle measurement in many fields

Magnetic sensors can be used in a wide range of fields, especially in environments in which the components can be exposed to dirt and loads and if the absolute accuracy is not mandatory. These applications include:

+ Linear encoders for dowel drilling stations, parquet floor production, tubular film packaging (MagLine Micro)

+ CT patient tables, mirror tracking (solar power stations), format circular saws, stone cutting (MagLine Basic)

+ Stage equipment, forklift trucks, waste and scrap metal presses, cutting stone (MagLine Macro)

+ Wind power generators, elevators, pipe bending systems, access control systems (MagLine Roto)

The overview of the product ranges shows which applications require which type of magnetic measuring equipment. Within the product families all components from the sensor to the magnetic strip and the display are ideally combined.

Note: Magnetic sensors are part of the MagLine product range.

Những lợi ích khi bạn mua hàng tại Công ty AMECH:

- Sản phẩm có nguồn gốc xuất xứ rõ ràng nên bạn dễ dàng thay thế, nâng cấp linh kiện khi cần thiết;

- Sản phẩm trước khi xuất xưởng luôn được kiểm tra nghiêm ngặt;

- Sản phẩm được bảo hành 12 tháng nên bạn có thể yên tâm khi sử dụng;

- Trang web bán hàng của Công ty AMECH đã đăng ký và được kiểm tra bởi Bộ Công Thương (link đến thông tin của AMECH tại trang web của Bộ Công Thương ở phía cuối trang web) nên bạn có thể yên tâm khi mua hàng.

THÔNG SỐ KĨ THUẬT CHÍNH

Model: MSK5000

Incremental, digital interface, resolution 1 μm, scaling factor 1250

Profile MSK5000:

+ Max. resolution 1 μm

+ Repeat accuracy ±0.01 mm

+ Repeat accuracy of ±1 increment

+ Status LED display

+ Works with magnetic tape MB500/1, MR500, MBR500

+ Reading distance ≤2 mm

+ Max. 200000 pulses/revolution in combination with MR500 or MBR500 (160 poles)

+ Optionally with reference point R or flexible reference marks FR.

Xuất xứ: GERMANY.

Miễn phí tư vấn, vận chuyển trong nội thành Hà Nội (xem thêm chính sách giao hàng của Amech)!

Liên hệ với chúng tôi công ty Amech để có thêm thông tin về kích thước và các loại cảm biến khác khác!

Giá và thông số kỹ thuật sản phẩm có thể thay đổi tùy theo model từng thời điểm mà không báo trước (do công ty chưa cập nhật kịp trang web). Cần liên hệ với công ty để có thông tin chính xác và giá cụ thể!

Quý khách vui lòng gửi mail để đặt hàng!

Sản phẩm đã được thêm vào giỏ hàng

0938.388.583

0938.388.583

sales.amech@gmail.com

sales.amech@gmail.com

Mở cửa: Từ 8:00 đến 20:30

(Tất cả các ngày

trong

tuần)

Mở cửa: Từ 8:00 đến 20:30

(Tất cả các ngày

trong

tuần)